The paper quality of paper factory largely depends on the pulping. The devillicate, brooming, swelling, hydration and

cutting of pulp is known as beating. Presently, the most common ones are conventional beater and single / double disc high/low concentration pulp grinder. As these equipment will break the fiber, reduce the product quality, impact the enterprise benefits and have less applicability on pulp in particular on waste paper pulp (which contains glue and ink etc.), additional heat dispersion equipment should be provided to remove the glue and ink etc.

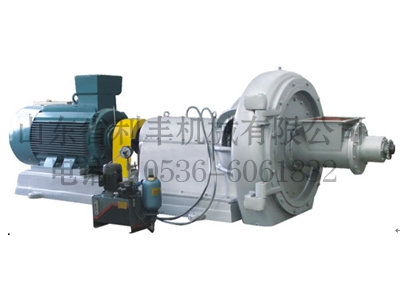

The newly developed LGMII series high concentration cone prefiner is new type beating equipment and suitable for the beating of various pulps. In particular, it can solve the beating and cold / heat dispersion of waste paper pulp at the same time. This equipment is produced through the latest patented technology that approaching or meeting the overseas advanced stage and featured in high assembly accuracy, uniform beating quality, low noise, low power consumption, high pulping concentration, less fiber cut, noticeable devillicate and brooming effect and good fiber toughness. It can effectively protect the fiber length of leaf wood and grass and the once pulping can increase the beating degree by 15 - 20°SR. Compared with traditional beater and single / double disc pulp grinder, it increases the efficiency by 2 - 3 times. The yield of one LGMII high concentration cone prefiner is equal to the yield of 3 - 4 ZDPIIФ450 double disc pulp grinders in series. In particular, for the waste paper pulp, it can effectively separate and remove the hot-melt adhesive, glue and ink of the waste paper pulp in addition to high efficiency beating.

II. Main Specifications and Parameters

|

Specification

Parameters |

ZGMI -22 |

ZGMI -30 |

ZGMI -37 |

ZGMI -45 |

ZGMI -55 |

ZGMI -75 |

ZGMI -90 |

ZGMI -110 |

ZGMI -132 |

ZGMI -160 |

ZGMI -200 |

ZGMI -250 |

ZGMI -315 |

|

Production capacity T/D |

10-15 |

12-18 |

15-22 |

20-25 |

25-30 |

30-45 |

35-50 |

45-65 |

55-75 |

65-95 |

80-120 |

100-150 |

125-190 |

|

Pulping concentration (%) |

15-35 |

15-35 |

15-35 |

15-35 |

15-35 |

15-35 |

15-35 |

15-35 |

15-35 |

15-35 |

15-35 |

15-35 |

15-35 |

|

Main motor power (kW) |

22 |

30 |

37 |

45 |

55 |

75 |

90 |

110 |

132 |

160 |

200 |

250 |

315 |

|

Rotor speed (rPM) |

2940 |

2950 |

2950 |

2970 |

2970 |

2970 |

2970 |

2980 |

2980 |

2980 |

2980 |

2980 |

2980 |

|

Feeding screw dia. (mm) |

Ф100 |

Ф100 |

Ф125 |

Ф125 |

Ф125 |

Ф140 |

Ф150 |

Ф150 |

Ф175 |

Ф175 |

Ф200 |

Ф200 |

Ф225 |

|

Feeding motor power (kW) |

1.1 |

1.1 |

1.5 |

1.5 |

1.5 |

2.2 |

2.2 |

2.2 |

3 |

4 |

5.5 |

5.5 |

7.5 |

|

Feeding port dimension (mm) |

200× 100 |

200× 100 |

200× 150 |

200× 150 |

200× 150 |

250× 150 |

300× 150 |

300×150 |

300×200 |

300×200 |

350×250 |

350×250 |

400×300 |

|

Discharge port dimension (mm) |

250× 80 |

250× 80 |

300× 80 |

300× 80 |

300× 80 |

300× 80 |

300× 100 |

300×100 |

300×150 |

300×150 |

350×200 |

350×200 |

400×250 |